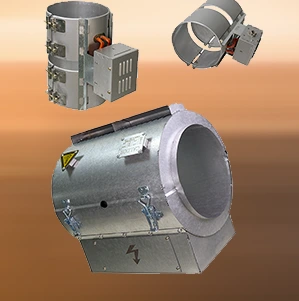

Where Heat-Cool combinations are used

Heat-Cool combinations are primarily used on extrusion machines. In some cases, they are also applied on injection molding machines, especially when processing materials like PVC. These systems are also widely used in recycling plants on various processing lines.

v

v