Thermal Insulation Jackets

Energy Efficiency Solutions

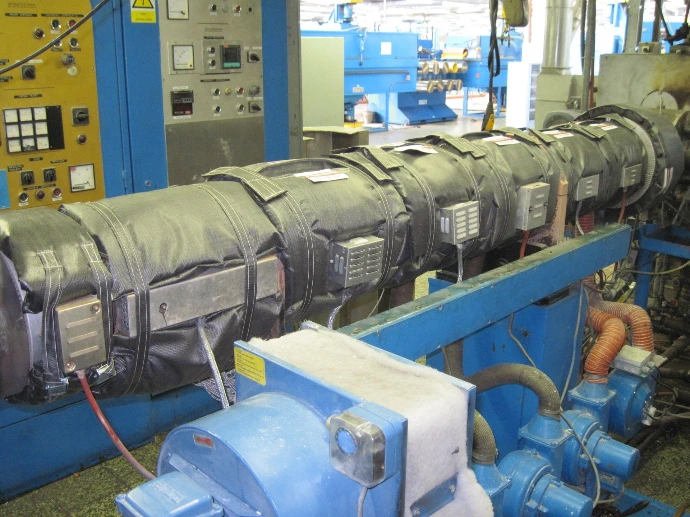

Caldor Heat Engineering designs and manufactures custom thermal insulation jackets engineered to significantly reduce heat loss and improve energy efficiency in industrial processes.

Applications

Thermal insulation jackets are ideal for polymer processing machinery and comparable industrial applications, including:

Barrel thermal insulation

Flat heater insulation

Insulating hoods and covers

Integrated insulation solutions

Our insulation systems help reduce surface temperatures, supporting compliance with industrial safety and energy-efficiency requirements.

Thanks to custom manufacturing, we are able to provide tailor-made insulation solutions precisely adapted to your equipment geometry, operating conditions, and thermal requirements.

As a manufacturer, Caldor Heat Engineering delivers durable, efficient, and application-specific thermal insulation solutions designed to optimize process performance and energy savings.

Key Features

Energy Efficiency : Significantly reduces heat loss, helping lower energy consumption and operating costs.

Custom-Engineered Design : Manufactured to fit specific equipment geometries, ensuring optimal insulation performance.

High-Temperature Resistance : Designed for continuous operation in demanding industrial environments.

Reduced Surface Temperatures : Improves workplace safety by lowering external surface temperatures.

Durable Industrial Construction : Built with high-quality insulation materials for long service life and mechanical resistance.

Easy Installation and Removal : Flexible jacket design allows quick installation, maintenance, and reusability.

Process Stability : Helps maintain consistent process temperatures and improves overall system efficiency.

Industrial Applications

Caldor Heat Engineering’s thermal insulation jackets are designed for a wide range of industrial processes where heat retention, energy efficiency, and operator safety are critical.

Typical applications include:

Plastics and Polymer Processing : Extruders, injection molding machines, barrels, and dies

Chemical and Process Industry : Reactors, vessels, piping, and process equipment

Oil, Gas, and Energy Systems : Valves, flanges, pumps, and heat-traced components

Food and Beverage Processing : Process vessels, tanks, and heating systems

Industrial Heating Equipment : Heaters, hot plates, thermal units, and heat exchangers

Mechanical and Industrial Plants : Machinery requiring thermal protection and temperature stability

Designed for demanding environments, our insulation jackets help reduce heat loss, improve process efficiency, and enhance operational safety across a wide range of industries.

Thermal Insulation Jackets – Industrial Energy Efficiency Solution

Thermal insulation jackets are industrial insulation solutions specifically designed to reduce heat loss, improve energy efficiency, and protect equipment and personnel in high-temperature processes. They are engineered to fit around components such as pipes, valves, flanges, vessels, barrels, extruders, and industrial heating equipment. Each jacket is manufactured using high-performance insulating materials, enclosed within a durable outer layer designed to withstand harsh industrial conditions.

By creating an effective thermal barrier, insulation jackets significantly minimize heat dissipation from hot surfaces while maintaining stable process temperatures. The flexible, removable design allows easy installation and access for maintenance, inspection, or equipment replacement—without compromising insulation performance. This makes thermal insulation jackets a practical and efficient solution for both new installations and retrofit applications.

Thermal insulation jackets are widely used across a broad range of industries, including plastics and polymer processing, chemical and process industries, energy systems, food and beverage production, and industrial manufacturing plants. They are valued for their ability to reduce surface temperatures, enhance workplace safety, and improve overall process stability, while supporting compliance with energy efficiency and safety standards.

One of the key advantages of thermal insulation jackets is their ability to deliver immediate energy savings, often reducing heating energy consumption by 20–50%, with a short return on investment. Their low maintenance requirements, long service life, and custom-engineered construction make them a reliable and cost-effective insulation solution for demanding industrial environments.

Designed for continuous operation at elevated temperatures and tailored to specific equipment geometries, thermal insulation jackets provide a scalable, durable, and efficient insulation solution wherever thermal energy conservation and process optimization are critical.

Technical & Commercial Inquiries for Custom - Engineered Ceramic Band Heaters

Contact our engineering team to submit technical specifications and request detailed quotations for customer-focused, application-specific ceramic band heater solutions..