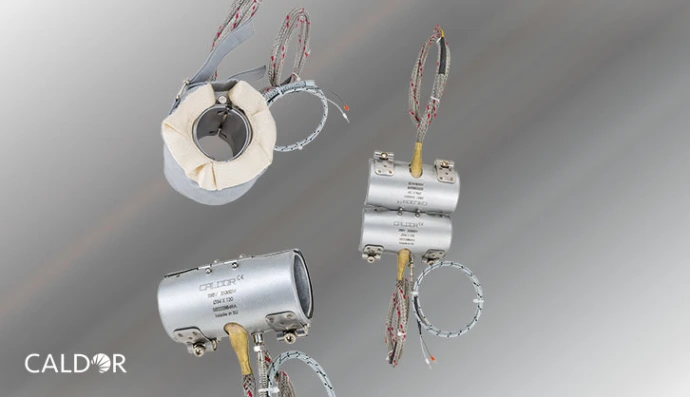

At Caldor, quality is not an isolated step—it is embedded throughout the entire production process. Each load bank heating element is manufactured:

- From high-temperature resistant alloys suitable for continuous and cyclic load operation

- Using tight dimensional and electrical tolerances to ensure uniform load distribution

- In compliance with recognized industrial quality standards

- With designs optimized for airflow, cooling efficiency, and stable resistance values

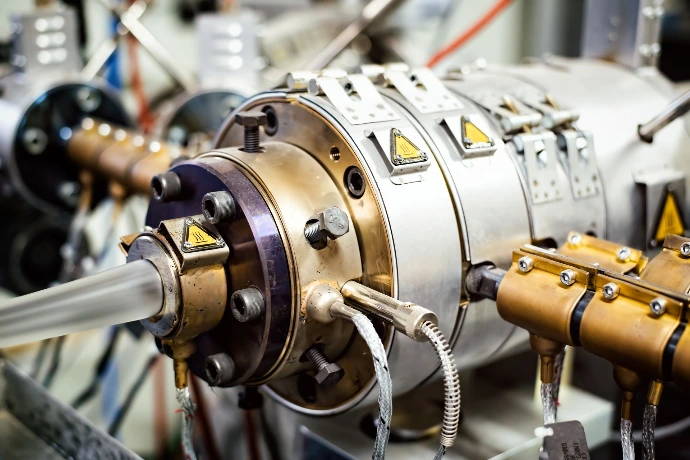

While our production lines use modern machinery and controlled processes, manual visual inspection remains essential. Certain defects can only be identified by the trained eye of experienced technicians. This balance between automation and craftsmanship is a defining element of Caldor’s manufacturing philosophy.