High-Performance Ceramic Band Heaters

Precision Heating for Your Industrial Process

Unlock rapid, reliable thermal performance with Caldor’s Ceramic Band Heaters — engineered for high-temperature applications and long-term operation. Whether you’re optimizing plastic processing, extrusion, or industrial heating systems, our solutions deliver consistent heat where it matters most

Request a quote!

Ceramic Band Heater Manufacturing

Performance, Temperature & Applications

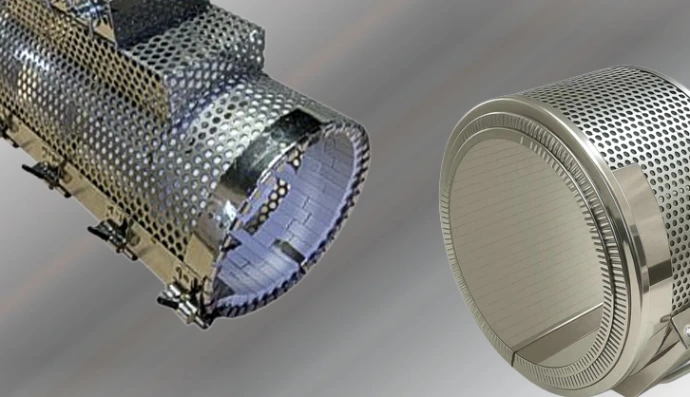

Caldor Heat Engineering designs and manufactures ceramic band heaters with precision engineering and rigorous quality control to support demanding industrial heating applications. These heaters feature a ceramic insulated core and rugged metal cladding, producing superior thermal transfer and longevity under continuous use.

Our ceramic band heaters are specifically engineered to deliver uniform heat distribution and rapid thermal response — qualities essential for processes requiring consistent and stable temperature control. Thanks to the ceramic insulation, these elements can withstand elevated operating temperatures typically up to 450°C in standard configurations, with custom options available to meet higher thermal requirements.

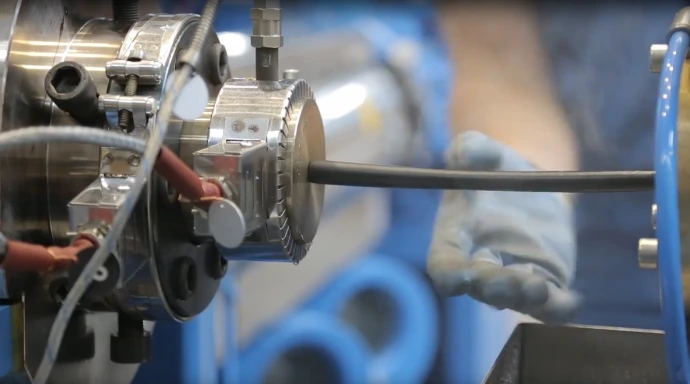

Ideal applications include cylindrical components such as barrels, pipes, and nozzles, where targeted heating is crucial for efficiency and product quality. Ceramic band heaters are widely used in industries such as plastics processing, packaging, and other high-heat industrial environments.

Key Features

High Operating Temperature Capacity: Designed to operate reliably at elevated temperatures, ensuring stable heating performance for demanding processes.

Uniform Heat Transfer: Ceramic insulation promotes efficient and even thermal distribution across the heater surface.

Robust Construction: Available with protective claddings including aluminized steel, stainless steel, or galvanized steel, customized to environmental demands.

Customizable Configurations: Voltage and connection options tailored to your system’s specifications — including single-phase, three-phase, and special connection features.

Integration Options: Optional cut-outs, thermocouple bridges, and reinforced mounting configurations for seamless installation.

Industrial Applications

Caldor’s ceramic band heaters are versatile across a wide range of industrial systems where precise temperature control is critical:

Plastic Processing and Injection Molding: Maintain melt temperatures on extruder barrels and injection machine components.

Packaging Machinery: Ensure consistent heat for sealing, forming, and material handling operations.

Extrusion Lines: Reliable heating of extruder barrels and dies for uniform material flow.

Heat Forming and Industrial Equipment: Provide stable heat for a variety of machinery requiring high-temperature operation.

Custom Industrial Systems: Flexible design matches complex heating profiles across specialty applications.

Why Choose Caldor’s Ceramic Band Heaters

Engineering Excellence:

Designed and manufactured to the highest industrial standards with strict quality oversight.

Thermal Efficiency:

Superior ceramic insulation enhances energy transfer, reducing heat loss and operational costs.

Custom Solutions:

We tailor each heater to your dimensions, power requirements, and installation needs — ensuring the best fit for your process.

Durability in Harsh Conditions:

Built to endure continuous operation in high-temperature, industrial environments with minimal maintenance.

Trusted Industrial Partner:

Backed by Caldor’s deep experience in industrial heating systems and commitment to reliable delivery and support.

Order Information

Provide the following details so we can tailor the right solution for you:

Desired electrical power (W) and supply voltage (V)

Diameter (mm) and width (mm) of the band

Sensor cavity dimensions (if required)

Position of power connection (angle relative to the closure)

Connector type or cable specification and length

A ceramic band heater is an industrial heating device specifically designed to heat cylindrical components such as pipes, barrels, extruder cylinders, and nozzles. It is constructed around a flexible ceramic insulation core, which is enclosed within a robust metal sheath, typically manufactured from steel or stainless steel. Heat is generated by passing an electric current through the heating element, causing the ceramic insulation to heat up and efficiently transfer thermal energy to the surface of the component being heated.

Ceramic band heaters are widely used across a broad range of industrial processes, including plastic injection molding, extrusion, packaging machinery, and food processing equipment. They are valued for their high thermal efficiency, excellent heat transfer characteristics, and ability to maintain stable, uniform temperatures over extended operating periods. Their design allows them to withstand high operating temperatures and perform reliably in harsh industrial environments, while remaining relatively easy to install and service.

One of the key advantages of ceramic band heaters is their low thermal mass, which enables rapid heat-up times and quick response to temperature adjustments. This results in improved process control and reduced energy consumption. In addition, ceramic band heaters are highly versatile and customizable, allowing them to be manufactured to fit standard or irregular shapes and specific application requirements. With a long service life and minimal maintenance needs, they represent a dependable and cost-effective heating solution for demanding industrial applications.

Technical & Commercial Inquiries for Custom - Engineered Ceramic Band Heaters

Contact our engineering team to submit technical specifications and request detailed quotations for customer-focused, application-specific ceramic band heater solutions..