Finned Tubular Heaters – Industrial Air & Gas Heating Solution

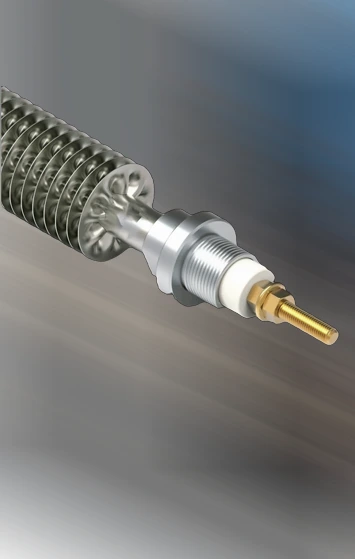

Finned tubular heaters are electric heating elements specifically engineered for efficient heating of air and non-corrosive gases in industrial systems. By integrating spiral-wound fins onto a robust tubular heating element, these heaters significantly increase the convective surface area, enabling higher heat transfer efficiency, lower sheath temperatures, and extended service life compared to conventional open-coil heaters. Designed for safety, durability, and consistent performance, finned tubular heaters are a reliable solution for demanding industrial air-heating applications.

Finned Tubular Heaters

Industrial Electric Heating Elements

Finned tubular heaters are electric heating elements specifically designed for efficient heating of air and non-corrosive gases in industrial and commercial applications. By integrating precision-wound fins onto a tubular heating element, the effective heat transfer surface is significantly increased, allowing higher power output, improved thermal efficiency, and lower sheath temperatures compared to standard tubular or open-coil heaters.

Caldor’s finned tubular heaters are engineered for continuous operation in demanding environments where reliability, safety, and long service life are essential. The finned construction ensures uniform heat dissipation, reduces thermal stress on the sheath, and minimizes maintenance requirements, making these heaters a robust and cost-effective solution for air heating systems.

Designed as a safer alternative to open coil heaters, finned tubular heaters reduce the risk of fire caused by dust or combustible particles and limit exposure to live electrical components. Their rugged mechanical design allows stable operation in high airflow, vibration-prone, and industrial installations.

Caldor offers custom-manufactured finned tubular heaters, tailored to project-specific requirements such as power rating, dimensions, fin material, sheath alloy, mounting method, and electrical connection. This flexibility ensures optimal performance across a wide range of applications, including industrial ovens, drying systems, load banks, HVAC equipment, wind turbines, marine installations, and large commercial heating systems.

By combining efficient heat transfer, durable construction, and application-specific material selection, Caldor’s finned tubular heaters deliver reliable performance and long-term operational stability in modern industrial heating systems.

Key Features

- Enhanced Heat Transfer Efficiency : Precision-wound fins significantly increase the convective surface area, ensuring efficient heat dissipation for air and non-corrosive gas heating.

- Lower Sheath Temperature : Optimized fin geometry reduces sheath operating temperature, extending heater lifespan and improving overall safety.

- Robust Tubular Construction : Built on heavy-duty tubular heating elements designed for continuous operation in industrial environments.

- Safe Alternative to Open-Coil Heaters : Minimizes fire risk from dust or airborne particles and reduces exposure to live electrical components.

- Customizable Design : Power rating, watt density, dimensions, fin material, sheath alloy, and mounting options can be tailored to application requirements.

- Wide Range of Applications : Suitable for industrial ovens, drying systems, load banks, HVAC units, wind turbines, marine installations, and commercial heating systems.

- Resistance to Harsh Conditions : Designed to perform reliably in high airflow, vibration-prone, and demanding industrial installations.

- Multiple Sheath & Fin Material Options : Available in carbon steel, stainless steel, and high-temperature alloys to match environmental and corrosion conditions.

- Easy Installation & Maintenance : Compatible with various mounting accessories such as bulkhead fittings, brackets, collars, and locator washers.

- Long Service Life & Low Maintenance : Durable construction and efficient thermal management reduce downtime and maintenance costs over the heater’s operating life.

Product Overview

- Power range from 100 W up to 15 kW per heater (higher outputs achievable through multiple heater configurations or assemblies)

- Designed for atmospheric or low-pressure air and gas heating applications Ideal for forced convection systems and open or ducted airflow environments

- Tubular heating elements with precision-wound fins Fins significantly increase the heat transfer surface, optimizing convective heating efficiency

- Sheath materials available Stainless steel (AISI 304 / 316 / 321), Incoloy®, or other alloys depending on operating temperature and environment

- Fin materials Carbon steel or stainless steel, securely bonded to the sheath for improved thermal conductivity

- Single-phase or three-phase electrical configurations

- Custom voltage, watt density, fin geometry, and connection options available

Advantages

- High thermal efficiency for air and gas heating Enlarged surface area enables higher power output with lower sheath temperatures

- Safer alternative to open-coil heaters Reduced fire risk from dust or airborne particles and minimized electrical exposure

- Long service life Lower operating temperatures and robust mechanical construction reduce thermal stress and material fatigue

- Flexible design options Heater dimensions, power density, fin spacing, materials, and mounting accessories can be adapted to the application

- Cost-effective solution High efficiency and low maintenance requirements result in reduced operating costs over time

- In-house engineering and manufacturing control Ensures consistent quality, traceability, and repeatable performance across production batches

Operating Conditions & Configurations

- Standard industrial execution for non-hazardous environments

- Ambient operating temperatures From –40 °C up to +80 °C (higher ambient temperatures possible with adapted designs)

- Process temperature capability Suitable for air and gas heating applications up to 750–800 °C, depending on sheath and fin material

- Designed for dry air and non-corrosive gas heating Not intended for direct immersion in liquids

- Installation environments Industrial plants, commercial facilities, outdoor systems, and enclosed equipment housings

- Resistant to vibration and high airflow conditions Suitable for forced-air systems, blowers, and ventilation ducts

- Mounting orientations Horizontal or vertical installation supported, depending on airflow direction and system design

Optional accessories

Bulkhead fittings, mounting brackets, collars, and locator washers

Protective surface treatments or coatings for humid or mildly corrosive environments

Industrial Applications

Caldor’s finned tubular heaters are engineered for efficient and reliable heating of air and non-corrosive gases in industrial and commercial systems where controlled airflow heating is required:

Industrial Ovens & Drying Systems

Uniform air heating for curing, drying, baking, and heat-treatment processes in continuous or batch operations.

Process Machinery & Production Lines

Air heating for temperature stabilization, preheating, and environmental control in heavy-duty industrial equipment.

Load Bank & Testing Systems

Controlled air heating for electrical load banks and testing equipment, ensuring accurate performance simulation and heat dissipation.

HVAC & Ventilation Systems

Air heating for heating, ventilation, and air-handling units in industrial plants, commercial buildings, hospitals, and public facilities.

Renewable Energy & Wind Turbine Systems

Anti-freeze and de-icing air heating applications for nacelles, control cabinets, and critical components exposed to low temperatures.

Marine & Port Infrastructure

Air heating solutions for ships, decks, containers, and port facilities, designed to operate reliably in humid and demanding environments.

Food, Packaging & Plastics Industries

Hot air generation for drying, forming, and process air heating where stable temperature control and continuous operation are required.

Custom & Engineered Air Heating Systems

Tailor-made solutions for specialized applications requiring precise airflow heating, specific power densities, and application-adapted materials.

Technical & Commercial Inquiries for Custom-Engineered Finned Heaters

Contact our engineering team to submit your technical specifications and request detailed quotations for customer-focused, application-specific Finned heater solutions.