Cast heaters

Technical & Commercial Inquiries for Cast Heaters

Engineered for high-performance and durability in demanding thermal applications.

For custom designs and detailed quotations, please contact our engineering team..

Request a quote!

Cast-In Heaters

High-Performance Embedded Heating Solutions

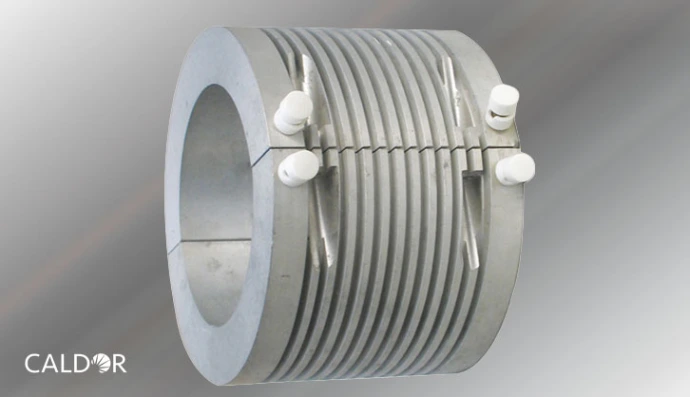

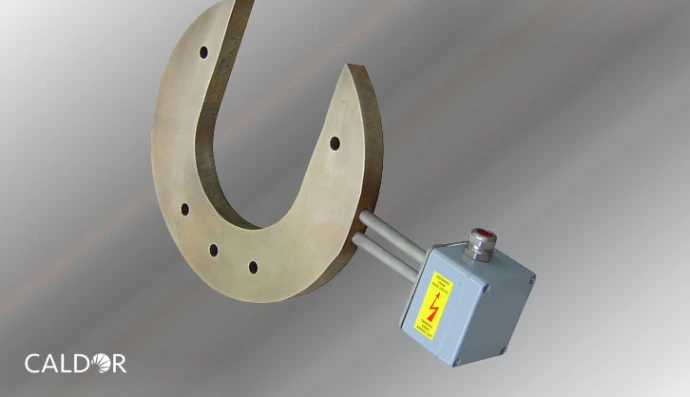

Robust Cast-In Heaters for Uniform Heating of Cylindrical and Flat Surfaces

Our cast-in heaters are precision-engineered heating elements embedded in high-strength materials such as aluminum or bronze, designed to provide efficient and uniform heat transfer in industrial applications. These heaters are ideal for use in plastic extrusion barrels, dies, tanks, and high-load machinery where thermal stability and mechanical durability are essential.

Manufactured with cast-in technology, they offer excellent heat conductivity, resistance to thermal shock, and long service life under continuous operation. Cast-in heaters support power densities up to 5 W/cm² and operate reliably at temperatures up to 450 °C, depending on the alloy and application. Integrated cooling channels, thermocouples, and custom mounting options are also available for tailored performance.

Key Features

- High Mechanical Strength : Cast in durable materials such as aluminum or bronze, offering excellent resistance to vibration, pressure, and mechanical stress.

- Superior Heat Transfer: Direct metal-to-metal contact ensures uniform heat distribution and fast thermal response across the heated surface.

- Integrated Cooling Options : Available with embedded cooling channels (air or water) for enhanced temperature control and cycle time reduction.

- High Power Density : Supports power densities up to 5 W/cm², ideal for high-demand heating applications.

- Custom-Engineered Designs : Fully customizable in terms of shape, bore size, wattage, voltage, and mounting configuration to fit specific application requirements.

- Temperature Sensor Integration : Compatible with built-in thermocouples, RTDs, or sensor cavities for precise process control.

- Extended Service Life : Designed for long-term reliability even in continuous operation and high-temperature environments (up to 450 °C).

- Corrosion & Oxidation Resistance: Material selection tailored to resist harsh environments, including moisture, chemicals, and industrial contaminants

Industrial Applications

Caldor’s cast-in heaters are designed to perform in demanding industrial environments where precise heat transfer, mechanical durability, and thermal stability are critical. Common application areas include:

Plastic & Rubber Extrusion

Barrel and die heating in extrusion lines, blow molding, and injection molding equipment.

Blown Film and Sheet Production

Maintaining consistent temperature profiles in high-speed film and sheet extrusion systems.

Packaging Machinery

Used in sealing stations, cutting systems, and form-fill-seal machines requiring stable and uniform heat.

Die Casting & Metal Processing

Preheating of dies, molds, platens, and other components exposed to high thermal cycling.

Food & Beverage Equipment

Applied in cooking plates, hot melt systems, and liquid containment units requiring sanitary and durable heating.

Chemical & Pharmaceutical Industries

Heating of process tanks, fluid transfer systems, and jacketed vessels with corrosion-resistant cast-in designs.

Textile & Laminating Systems

Provides flat or curved surface heating for fusing, laminating, or heat-sealing fabrics and composites.

Semiconductor & Electronics Manufacturing

Delivers localized, stable heat to fixtures, tooling, and sensitive production environments where precision matters.

Why Choose Caldor’s Mica Band Heaters

Caldor’s cast-in heaters combine engineering precision, high-quality materials, and application-specific customization to deliver superior performance in demanding thermal environments.

With decades of expertise in industrial heating, we design and manufacture cast-in solutions that offer outstanding thermal conductivity, structural durability, and long service life. Our heaters are built using aluminum, bronze, or stainless steel casting, depending on the operating environment, and are designed to integrate seamlessly into your process.

We offer full customization in shape, size, watt density, voltage, mounting configuration, and sensor integration—ensuring the heater is optimized for your specific application. From extrusion barrels and dies to sealing plates and process tanks, Caldor heaters provide stable, uniform heat with minimal maintenance.

Our dedicated engineering team works closely with clients to provide expert support, fast quotations, and long-term reliability you can trust.

Choose Caldor for precision-crafted cast-in heating solutions that enhance efficiency, extend equipment life, and reduce downtime.

Order Information

Provide the following details so we can tailor the right solution for you:

Caldor specializes in the design and manufacturing of high-performance cast-in heaters, engineered to deliver consistent and efficient thermal transfer in the most demanding industrial applications. Our cast-in heating solutions are widely used across sectors such as plastics and rubber extrusion, die casting, food processing, packaging machinery, chemical and pharmaceutical production, and other heat-intensive processes requiring precision and reliability.

Our cast-in heaters stand out for their exceptional mechanical strength, uniform heat distribution, and long service life, even under extreme temperature and mechanical stress. Each unit is custom-engineered to meet specific application needs, with flexible options for size, shape, wattage, voltage, integrated cooling channels, and sensor compatibility. Constructed using robust materials such as aluminum or bronze, our heaters are ideal for both heating and structural integration into machinery.

At Caldor, we are committed to combining technical expertise with responsive customer support. Our engineering team works closely with clients to provide guidance during the design and specification process—ensuring optimal performance and seamless integration into their systems. From initial consultation to post-sale service, we prioritize long-term reliability and efficiency.

We thank you for considering Caldor as your trusted partner in cast-in heating technology and look forward to building long-lasting, value-driven collaborations with you.

Technical & Commercial Inquiries for Custom-Engineered Cast-In Heaters

Contact our engineering team to request detailed quotations and submit technical specifications for custom-designed, application-specific cast-in heating solutions. We offer expert guidance and full design flexibility to meet the thermal, mechanical, and environmental requirements of your industrial process.