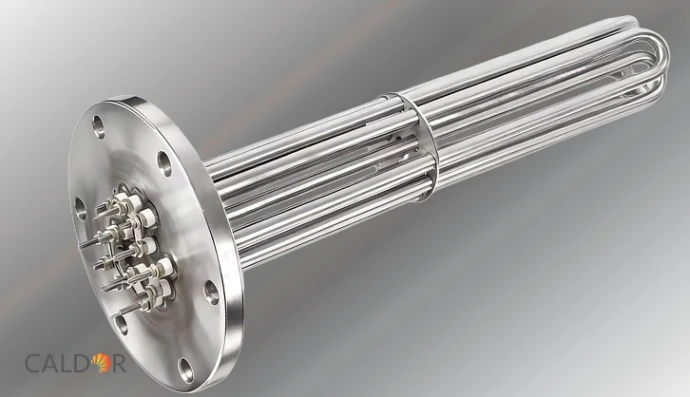

Flange immersion heaters

Electrical flange immersion heaters are designed for efficient heating and precise temperature maintenance of liquids, gases, or process mixtures in both static and circulating systems.

Contact our engineering team to select and design heating solutions precisely matched to your system requirements.

Request a quote!

Electrical Flange Immersion Heaters – Caldor Solution

Electrical flange immersion heaters are engineered by CALDOR HEAT ENGINEERING SRL for efficient heating and precise temperature maintenance of liquids, gases, or process mixtures under both static and circulating operating conditions.

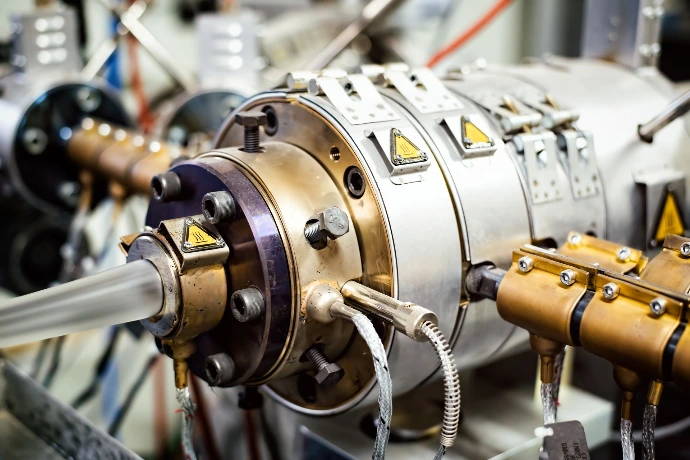

Designed for direct installation into tanks, vessels, and pipelines, Caldor flange immersion heaters ensure uniform heat distribution, high thermal efficiency, and long service life, even in demanding industrial environments. Each unit is custom-manufactured to meet specific process requirements, including power density, operating temperature, medium compatibility, and mechanical constraints.

The design is based on the customer’s process conditions, including the type and properties of the fluid to be heated, inlet and outlet temperatures, operating pressure, heat-exchange conditions (static or flowing), and environmental requirements (ATEX or non-ATEX, onshore or offshore).

Flange immersion heaters are suitable for heating a wide range of fluids, such as water, thermal fluids, oils, heavy fuel, corrosive liquids, gas mixtures, natural gas, and many other process media.

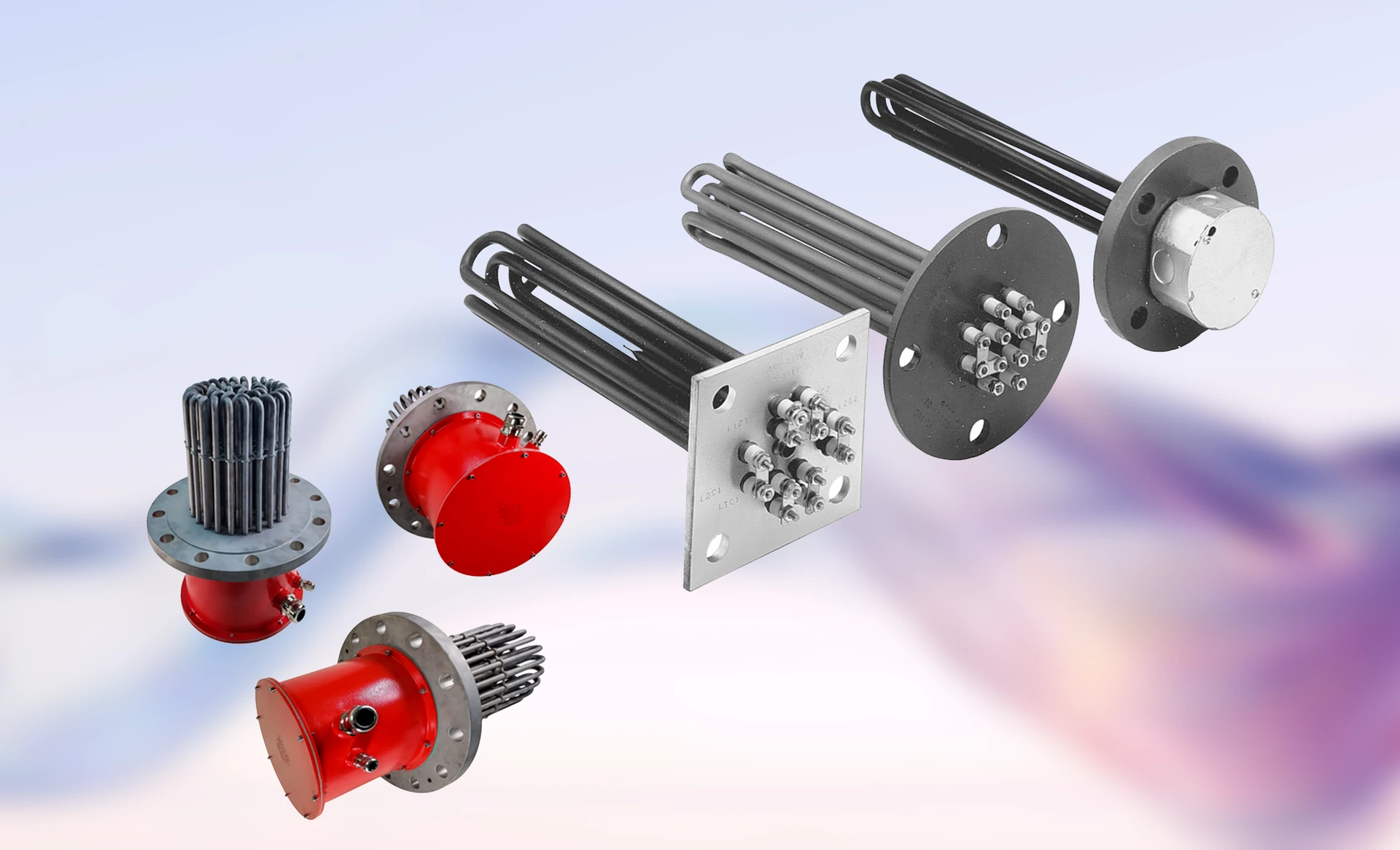

Flange immersion heaters are available in straight or L-shaped configurations.

Key Features

Custom-designed based on customer process conditions and operating parameters

Suitable for heating liquids, gases, and fluid mixtures

Designed for both static and circulating systems

Robust flange-mounted construction for secure and reliable installation

Available in straight or L-shaped element configurations

Wide range of sheath materials for corrosive and high-temperature media

Compatible with ATEX and non-ATEX environments

Suitable for onshore and offshore applications

High thermal efficiency and long service life

Product Overview

- Heating power up to 5 MW (5,000 kW)

- Watt density ranging from 0.1 to 20 W/cm², depending on fluid properties and operating conditions

- Process temperature up to +650 °C

- Rated voltage up to 690 V

- Custom mechanical and electrical design based on application requirements

Advantages

- Wide range of sheath materials, flange types, and construction options, tailored to customer process conditions

- Over 20 years of experience as a designer and manufacturer of industrial electric heating solutions

- Equipment available for safe areas and hazardous areas

- Compliance with ATEX, IECEx, and NEC (NEC 500 / NEC 505) requirements

- Full in-house control of engineering, manufacturing, testing, and quality assurance

- Optimized thermal performance, reliability, and service life for demanding industrial applications

Advantages

- Normal (non-ATEX) environments

- Hazardous areas:

ATEX (EU Directive 2014/34/EU)

IECEx

NEC Class I / Division 1–2 and NEC 505 (Zone system)

- Extreme ambient temperatures: from –60 °C to +80 °C

- Process media temperature range: from –270 °C (3 K) up to +1000 °C, depending on design

- Suitable for liquids, gases, solids, and mixtures

- Onshore and offshore installations

- Resistant to salt atmospheres and aggressive industrial environments

- Operating pressure up to 250 bar, compliant with PED (Pressure Equipment Directive)

Design & Customization

Flange immersion heaters are designed and manufactured according to customer-specific process requirements. Each solution is engineered based on fluid characteristics, operating temperatures, pressure levels, power density limits, and installation constraints.

Mechanical design parameters—including flange type, element configuration (straight or L-shaped), and material selection—are defined to ensure efficient heat transfer, mechanical strength, and long-term reliability. Electrical design includes voltage, power rating, control integration, and safety components in compliance with applicable standards.

Environmental conditions such as ATEX or non-ATEX classification, onshore or offshore installation, ambient temperature, and corrosion exposure are carefully evaluated to deliver a solution precisely matched to the application.

Industrial Applications

Caldor’s flange immersion heaters are used across a wide range of industrial systems where reliable and controlled heating of fluids is essential:

Chemical & Petrochemical Processing: Heating and temperature maintenance of process fluids, corrosive media, and chemical baths.

Oil & Gas Industry: Preheating and temperature control of oils, fuels, gas mixtures, and process lines in onshore and offshore installations.

Water & Wastewater Treatment: Heating of process water, boiler feedwater, and treatment tanks.

Power Generation & Energy Systems: Heating of thermal fluids and auxiliary systems to ensure stable and efficient operation.

Food, Beverage & Pharmaceutical Processes: Controlled heating of liquids under hygienic and regulated conditions.

Custom Industrial Systems: Engineered solutions for specialized applications requiring precise thermal control in static or circulating systems.

Why Choose Caldor’s Flange Immersion Heaters

Caldor’s flange immersion heaters are engineered to deliver reliable, efficient, and safe heating solutions for demanding industrial applications. Each heater is fully customized to the customer’s process conditions, ensuring optimal performance and long service life.

Custom-Engineered Solutions:

Designed according to fluid properties, temperature, pressure, power density, and installation constraints.

Wide Media Compatibility:

Suitable for liquids, gases, solids, and corrosive or high-temperature process media.

ATEX, IECEx & NEC Compliance:

Available for hazardous and non-hazardous environments, including onshore and offshore installations.

Robust Construction:

High-quality materials, advanced manufacturing processes, and rigorous testing guarantee durability and reliability.

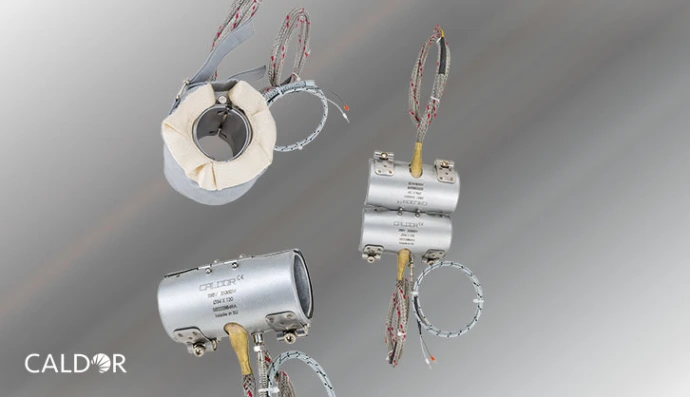

Precise Temperature Control:

Integration of thermostats, limiters, thermocouples, or PT100 sensors for accurate process and safety control.

Full In-House Expertise:

Engineering, manufacturing, testing, and documentation are managed by Caldor’s experienced technical team.

A flange immersion heater is an industrial heating device specifically designed for the direct heating and temperature maintenance of liquids, gases, or process mixtures in tanks, vessels, and pipelines. The heater consists of tubular heating elements mounted on a flange, allowing secure installation directly into the process equipment. Heat is generated by electrical resistance within the elements and transferred efficiently to the medium through direct immersion, ensuring uniform and controlled heating.

Flange immersion heaters are widely used across a broad range of industrial processes, including chemical and petrochemical plants, oil and gas installations, power generation systems, water and wastewater treatment facilities, and food, beverage, and pharmaceutical processing. They are valued for their high thermal efficiency, precise temperature control, and ability to operate reliably in both static and circulating systems.

Designed to withstand demanding industrial conditions, flange immersion heaters can operate at high temperatures and pressures while maintaining long-term reliability. Their robust construction, combined with carefully selected sheath materials and flange standards, ensures resistance to corrosion, thermal stress, and mechanical loads. The heaters can be equipped with integrated temperature control and safety devices, providing stable and uniform heating over extended operating periods.

One of the key advantages of flange immersion heaters is their flexibility in design and customization. Power rating, power density, element configuration, materials, and certification level (ATEX, IECEx, NEC) can all be tailored to specific process requirements. With efficient heat transfer, long service life, and straightforward installation and maintenance, flange immersion heaters represent a dependable and cost-effective heating solution for demanding industrial applications.Technical & Commercial Inquiries for Custom-Engineered Flange Immersion Heaters

Contact our engineering team to submit your technical specifications and request detailed quotations for customer-focused, application-specific flange immersion heater solutions.