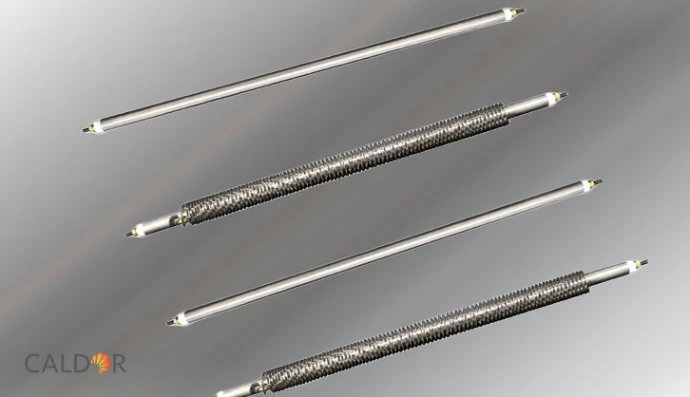

Straight Electric Heaters – Reliable Heating Solutions, ATEX Included

Straight heating elements are engineered for efficient and reliable heating of liquids, gases, and solid materials, covering a wide range of industrial applications. Designed to meet diverse process requirements, they can be customized in terms of dimensions, power, materials, and certifications, including ATEX for hazardous environments.

Request a quote!

Straight (Tubular) Heating Elements for Industrial Applications

Straight tubular heating elements are designed to provide efficient and reliable heating for liquids, gases, and solid materials across a wide range of industrial processes. Manufactured with compacted MgO insulation and high-quality metallic sheaths, these heaters ensure uniform heat transfer, mechanical robustness, and long service life, even in demanding operating conditions.

Available in standard or fully customized configurations, Caldor straight heating elements can be supplied with different diameters, lengths, power ratings, voltages, mounting options, and sheath materials. ATEX-certified versions are also available for use in hazardous environments, making them suitable for chemical, petrochemical, pharmaceutical, food processing, packaging, and general industrial applications.

Key Features

- Wide Application Range : Designed for efficient heating of liquids, gases, and solid materials across diverse industrial processes.

- High-Quality Sheath Materials : Available in stainless steels (AISI 304L, 316L, 321), Incoloy® alloys, titanium, copper, and carbon steel to match corrosive, high-temperature, or hygienic environments.

- Optimized Surface Load Design : Engineered with application-specific watt densities to ensure safe operation, long service life, and reliable heat transfer.

- Advanced MgO Insulation : Compacted, high-purity magnesium oxide insulation provides excellent dielectric strength and efficient thermal conductivity.

- Customizable Dimensions & Power : Manufactured in a wide range of diameters and lengths, with tailored voltage, wattage, and power distribution.

- Flexible Mounting & Integration Options : Suitable for immersion, air heating, cast-in, or surface-mounted applications, with various fixing and terminal configurations.

- Robust Sealing Solutions : Multiple sealing options available, including epoxy, silicone, hermetic, and ceramic sealing for harsh environments.

- ATEX Solutions Available : ATEX-compliant designs can be supplied for hazardous areas, depending on application requirements and zone classification.

- Strict Quality Control & EU Compliance : Manufactured in accordance with EU Directives 2014/35/EU (Low Voltage) and 2014/30/EU (EMC), with comprehensive electrical and mechanical testing.

- Engineered & Manufactured in Europe : Designed and produced in Romania, ensuring consistent quality, short lead times, and responsive engineering support.

Caldor specializes in the design and manufacturing of high-performance straight (tubular) heating elements, engineered to deliver reliable, efficient, and uniform heat transfer across a wide range of industrial applications. Designed for heating liquids, gases, and solid materials, our tubular heaters are widely used in tanks, vessels, pipelines, air heating systems, process equipment, and custom industrial machinery where durability and thermal stability are essential.

Caldor tubular heating elements are distinguished by their robust MgO-compacted construction, high-quality metallic sheaths, and optimized surface load design, ensuring consistent heat distribution and long service life. Capable of operating under demanding thermal and mechanical conditions, these heating elements provide stable performance even in corrosive, high-temperature, or continuous-duty environments.

Each straight tubular heater is custom-engineered to meet specific process requirements. Available options include a wide range of diameters and lengths, customized wattage and voltage configurations, tailored power distribution, multiple sheath material selections, and various sealing and terminal solutions. ATEX-compliant designs can also be supplied for hazardous area applications, depending on project specifications.

At Caldor, we combine deep engineering expertise with responsive technical support. Our engineering team works closely with customers throughout the design and specification process, ensuring seamless integration into existing systems while maximizing efficiency, safety, and operational reliability. From initial consultation to long-term support, we are committed to delivering dependable heating solutions that add measurable value to your industrial processes.

We appreciate your interest in Caldor straight (tubular) heating technology and look forward to supporting your projects with reliable, precision-engineered solutions.

Technical & Commercial Inquiries for Custom-Engineered Tubular Heating Elements

Contact our engineering team to request detailed quotations and submit technical specifications for custom-designed tubular heating elements. We provide expert engineering support and full design flexibility to meet the thermal, mechanical, and environmental requirements of liquid, gas, and solid heating applications.