Thermocouples – Precision Temperature Measurement Solutions

Caldor Heat Engineering supplies high-quality thermocouples, engineered for accurate and reliable temperature measurement in demanding industrial environments. Thermocouples are essential temperature sensors that convert temperature differences into a measurable electrical signal, enabling precise thermal monitoring across a wide range of applications.

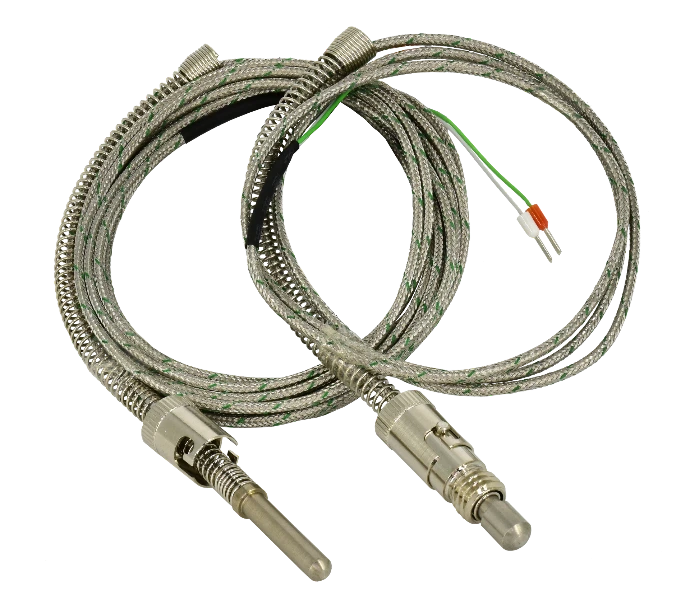

A thermocouple is a robust temperature sensor consisting of two dissimilar metal wires joined at a measuring junction. When exposed to temperature differences, the junction generates a voltage proportional to the temperature, which can be interpreted for accurate temperature measurement. Thermocouples are cost-effective, durable, and suitable for a broad temperature range, making them widely used in industrial processes, scientific equipment, and control systems.

Key Features

- Wide Temperature Range – Capable of measuring from low to very high process temperatures, depending on configuration.

- Fast Response – Rapid thermal response supports real-time process control.

- Robust and Reliable – Durable construction makes them suitable for harsh industrial environments.

- Cost-Effective – Low-cost sensor solution with long service life and minimal maintenance needs.

- Versatile Use – Compatible with various industrial sectors and temperature control systems.

Applications

Thermocouples supplied by Caldor Heat Engineering are used in a wide range of industrial applications, including:

Industrial furnaces and kilns

Extrusion and plastics processing

Oil, gas, and energy systems

Chemical and process automation

HVAC and environmental control

Laboratory and test equipment

Thermocouple Categories

Caldor Heat Engineering offers a comprehensive range of thermocouple types and configurations, including but not limited to:

Mantel Type Thermocouples – Standard sheathed sensors for general industrial use.

Metal Tube Sheathed Thermocouples – Enhanced protection for demanding environments.

Bayonet and Screw Type Thermocouples – Designed for insertion into process ports.

Headed Thermocouples – Thermocouples with connection heads for robust electrical interfacing.

Ceramic Tube Thermocouples – Suitable for ultra-high temperature applications.

Custom Configurations – Tailored designs based on application requirements.

Technical & Commercial Inquiries for Custom - Engineered Ceramic Band Heaters

Contact our engineering team to submit technical specifications and request detailed quotations for customer-focused, application-specific ceramic band heater solutions..