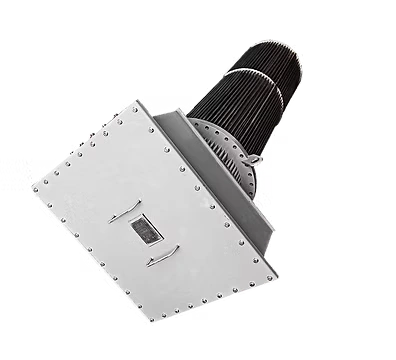

Caldor Heat Engineering designs and manufactures ATEX-compliant flanged immersion heaters for the safe and efficient heating of liquids and gases in hazardous areas.

Our immersion heaters are suitable for use in ATEX Zones 1, 2, 21, and 22, covering both gas and dust explosive atmospheres. Required conformity and documentation can be provided upon request.